1. Introduction In various industrial environments, operator comfort and safety directly impact work efficiency and long-term health. As a critical component of industrial vehicles...

READ MORE-

(86)-0571-82550327

-

info@bfseats.com

-

Universal Forklift Seats Manufacturers

Benfeng Seats as a professional manufacturer specializing in the field of off-road construction machinery seats, we focus on providing high-performance and high comfort driving seat solutions for our entire range of forklifts. Whether you are operating a powerful internal combustion forklift (diesel, gasoline, LPG, dual fuel), an environmentally friendly and quiet electric forklift, a versatile balance weight forklift, a storage forklift for channel operations (such as forward moving), an off-road forklift for complex road conditions, a side forklift for long material handling, a large container forklift, or an intelligent AGV automatic guided forklift, we can provide seat products that are precisely adapted.

Our forklift seats are made of black vinyl or comfortable flannelette fabric. The core functions include backrest angle adjustment, slide track fore and aft adjustment, shock absorption system and weight adjustment system to ensure the comfort and convenience of long-term driving. Rich selection of accessories (seat belts, micro switches, armrests, headrests, lumbar support) to meet personalized needs.

Choose us and you will receive:

· Exclusive customization: With a strong R&D team, we support customization based on samples and drawings, accurately matching special car models and needs.

· Quality assurance: Strict full process quality control system, professional laboratory testing to ensure reliability and durability.

· Powerful delivery: Annual production capacity of 200000 sets, 95% of key components are independently produced, with an average delivery time of only 15-20 days.

We are committed to becoming your trusted forklift seat partner, with professional manufacturing strength, to create safe, comfortable, and efficient workstations for forklift operators worldwide.

-

BF2-3AB EN13490 IT1+IT2 Certified Counterbalance Forklift Seat with Mechanical Suspension OPS Switch & Universal Multi-Function Mounting System Compatible with Toyota Jungheinrich

-

BF5-3 EN13490 IT1+IT2 Certified Suspension Seat with Safety Belt & OPS Switch | Wide-Operator Design Compatible with Hangcha, Nissan, TCM, Mitsubishi Forklifts

-

BF16 Low-Profile Vinyl Replacement Mechanical Suspension Seat for Material Handling Forklift Equipment - Black with EN13490 IT1+IT2

-

BF16MCD EN13490 IT1+IT2 & ISO7096 Dual-Certified Low-Profile Mechanical Suspension Seat Integrated seatbelt and OPS switch

-

BF17 Ergonomically Advanced High-Comfort Forklift Seat with Back Support EN13490 Certified for Optimal Operator Well-being

-

BF1-1 Durable Ergonomic Certified Forklift Seat for Internal Combustion Forklifts with Black Vinyl

-

BF1-2 Cost-effective black vinyl folding backrest forklift seat for warehouse vehicle fleets

-

BF1-3AB CE Certified Premium Adjustable Mechanical Suspension Forklift Seat for Electric Forklifts with Weight Adjustment & Armrests

-

BF2-1 Smart Automated Compatible Forklift Seat for AGV Forklifts with Integrated Micro Switch

-

BF2-2 Universa Electric stacker Operator Seat - Waterproof Black Coated 4-Way Stretch cloth PVC with OPS Sensor Switch & Adjustable Backrest Compatible with Hangcha, Toyota

-

BF5-2 CE-Certified Reliable Forklift Seat with Retractable Safety Belt Compatible with Hangcha, TCM, Nissan

-

-

In the demanding world of construction, agriculture, and material handling, industrial vehicle seats are far more than simple places to sit. They are a critical interface between h...

READ MORE -

Industry Enterprises Deepen Production Technology, Welding Positioning Devices Achieve Patent Breakthroughs Recently, a number of enterprises in the industry have focused on the in...

READ MORE -

At the recently held international logistics exhibitions, a number of domestic enterprises made a collective appearance with their innovative achievements in equipment seats. They ...

READ MORE -

Driven by both the recovery of global infrastructure investment and the release of demand for replacement of construction machinery, the global construction machinery seat market i...

READ MORE

European Standard EN13490 Safety Classifications for Forklift Seats

In the industrial vehicle sector, the safety of FORKLIFT SEATS is of paramount importance. The European standard EN13490 serves as the core metric for evaluating the quality and safety of forklift seats, primarily classifying them into IT1 and IT2 levels.

Key Technical Parameters

- EN13490 IT1: Suitable for flat surfaces, primarily testing basic protection capabilities.

- EN13490 IT2: Suitable for uneven terrain, with higher requirements for damping performance and strength.

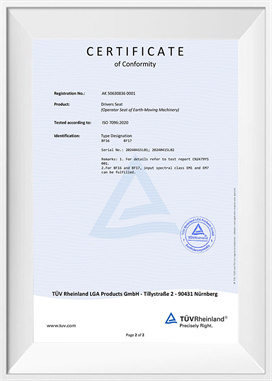

- ISO7096 EM1/EM7: Elastic testing standards for different vibration environments.

Industry Practice and Corporate Capability

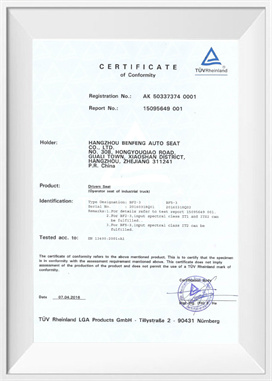

Hangzhou Benfeng Auto Seat Co., Ltd. strictly adheres to international standards. Their high-end series of seats have successfully passed EN13490 IT1, IT2, and ISO7096 EM1, EM7 certifications. The company has passed ISO9001 quality management system certification, ensuring that every seat from design to production meets the most rigorous global safety specifications.

The Role of Damping Performance in Forklift Seats and Health Value

The suspension system of FORKLIFT SEATS is not only about comfort but directly impacts the long-term health of the operator. A high-quality suspension system effectively reduces whole-body vibration (WBV) caused by uneven road surfaces.

Key Technical Parameters

- Suspension Travel: Determines the range of shock absorption the seat can handle.

- Weight Adjustment: Allows operators of different weights to achieve optimal damping effects.

- Damping Control: Controls the speed of vibration rebound to prevent secondary oscillation.

Industry Practice and Corporate Capability

Hangzhou Benfeng Auto Seat Co., Ltd. owns a modern production base of 14,000 square meters, focusing on the development of high-performance off-road construction machinery seat damping technology. With multiple national invention patents and utility model patents, the company is committed to providing ultimate damping solutions for material handling forklifts, loaders, and other equipment, boasting an annual output of 200,000 sets.

Application of OPS Operator Presence Sensing in Modern Forklift Seats

To enhance operational safety, modern FORKLIFT SEATS are generally integrated with OPS (Operator Presence Sensing) switches. This system ensures that when the operator leaves the seat, the forklift automatically cuts off travel or lifting power.

Key Technical Parameters

- Response Sensitivity: The speed at which the seat detects pressure changes.

- Compatibility: Whether it can seamlessly integrate with AGV automatic guided forklifts and other electric models.

- Integration Method: The degree of fusion between micro-switches and the seat structure.

Industry Practice and Corporate Capability

Hangzhou Benfeng Auto Seat Co., Ltd. is a leader in the intelligent R&D of FORKLIFT SEATS. The company not only produces seats with mechanical suspension but also develops seat products compatible with intelligent automation systems (such as model BF2-1), which are highly trusted by internationally renowned brands like Mitsubishi Logisnext and JUNGHEINRICH.

Standardization: JB/T13693-2019 and Forklift Seats

With the maturation of the industrial vehicle industry, the production standards for FORKLIFT SEATS have become increasingly standardized. The Chinese Machinery Industry Standard JB/T13693-2019 "Industrial Vehicle Driver Seat" is an important technical basis for this industry.

Key Technical Parameters

- Standard Number: JB/T13693-2019

- Scope of Application: Design, manufacturing, and acceptance of industrial vehicle driver seats.

- Core Drafting Units: Enterprises with top-tier technical strength in the industry.

Industry Practice and Corporate Capability

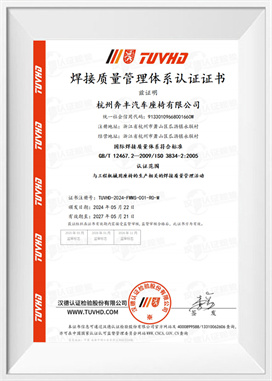

Hangzhou Benfeng Auto Seat Co., Ltd., established in 2007, is one of the standard-setting units of this important standard, demonstrating its profound technical accumulation. The company has been awarded the titles of "Zhejiang High-tech Enterprise" and "Specialized and New Enterprise." Holding ISO14001 environmental management system and ISO45001 occupational health and safety management system certifications, it is a promoter of industry standardization.

Customized Solutions for AGV and Special Vehicles

With the development of logistics automation, there is a growing demand for FORKLIFT SEATS suitable for AGVs (Automatic Guided Vehicles), cleaning equipment, and special operating conditions. Customized seats require specialized design based on the vehicle's spatial layout and specific functions.

Key Technical Parameters

- Installation Dimensions: Slide rail adjustment distance and base hole matching.

- Material Selection: Black vinyl, elastic fabric PVC, or single-mold polyurethane (eco-friendly).

- Special Functions: Such as waterproof coating, folding backrest, retractable seat belts.

Industry Practice and Corporate Capability

Hangzhou Benfeng Auto Seat Co., Ltd. specializes in providing customized solutions for material handling forklifts, tractors, cleaning equipment, and other machinery. The company has established long-term friendly relationships with top domestic and international brands such as Linde, KION, HANGCHA, and LiuGong. With strong R&D and design capabilities, it can provide precise FORKLIFT SEATS products for specific working conditions of different clients.

| Company Name | Hangzhou Benfeng Auto Seat Co., Ltd. |

| Year Established | 2007 |

| Production Base | 14,000 square meters |

| Annual Output | 200,000 sets |

| Key Certifications | ISO9001, ISO3834, ISO14001, ISO45001, CE, EN13490 IT1/IT2, ISO7096 EM1/EM7 |

| Key Partners | Mitsubishi Logisnext, NICHIYU, HANGCHA, EP, JUNGHEINRICH, Linde, KION, LiuGong, MIMA, GOODSENSE |

FAQ

What are the key safety certifications to look for when buying Forklift Seats?

When purchasing FORKLIFT SEATS, the most critical certifications to verify are the EN13490 IT1 and IT2 standards, which cover safety for both smooth and rough terrains. Additionally, ISO7096 EM1 and EM7 certifications are vital as they measure the seat's ability to attenuate vibrations. High-quality manufacturers like Hangzhou Benfeng Auto Seat Co., Ltd. ensure their products carry these certifications, alongside CE marking, to guarantee compliance with global safety regulations.

How does the suspension system in Forklift Seats affect operator productivity?

A robust suspension system in FORKLIFT SEATS significantly reduces whole-body vibration (WBV), which is a major cause of fatigue and long-term health issues for operators. By minimizing the impact of uneven surfaces, high-quality seats with mechanical suspension and weight adjustment features allow operators to work longer hours with greater comfort and focus. This directly translates to increased productivity and reduced downtime due to operator fatigue.

Can I get customized Forklift Seats for specific AGV models?

Yes, customization is a key service offered by leading manufacturers. Companies like Hangzhou Benfeng Auto Seat Co., Ltd. provide tailored FORKLIFT SEATS solutions that integrate specific features such as Operator Presence Sensing (OPS) switches, unique mounting interfaces, and specialized materials like waterproof fabrics or durable vinyl. These custom seats are designed to fit the exact spatial and functional requirements of specific AGV models and automated machinery.

What is the difference between EN13490 IT1 and IT2 ratings?

The EN13490 standard classifies industrial vehicle seats into two categories based on their application environment. IT1 rated FORKLIFT SEATS are designed for use on vehicles operating primarily on smooth surfaces. In contrast, IT2 rated seats are engineered for rough terrain and off-road conditions, offering superior damping capabilities and structural integrity. Choosing the correct rating is essential for ensuring both operator safety and seat longevity.

Why is the JB/T13693-2019 standard important for the Forklift Seat industry?

The JB/T13693-2019 standard, "Industrial Vehicle Driver Seat," sets the benchmark for the design and manufacturing of seats within the Chinese machinery industry. As a standard-setting unit, Hangzhou Benfeng Auto Seat Co., Ltd. demonstrates its leadership by adhering to these strict guidelines. This standard ensures that products maintain a high level of quality, safety, and compatibility with industrial vehicles, providing a reliable reference for both manufacturers and end-users.

中文简体

中文简体 English

English Français

Français Español

Español عربى

عربى