1. Introduction In various industrial environments, operator comfort and safety directly impact work efficiency and long-term health. As a critical component of industrial vehicles...

READ MORE-

(86)-0571-82550327

-

info@bfseats.com

-

Industrial Vehicle Seats Suppliers

-

BF1-2 Fold-Flat Industrial Seat for Platform Trucks with Space-Efficient 95° Forward Fold Design

-

BF1-3 Suspension Operator Seat for Stackers with Mechanical Damping for Stable Lifting

-

BF2-2 Universal Fit Flatbed Seat for Airport Tractors with 60° Recline, Retractable Seatbelt & Doc Box

-

BF2-3 Mechanical Suspension Seat for Platform Trucks with 40mm Stroke & Universal Mounting

-

BF5-2 Universal Ergonomic Seat for Stackers with Wide 60° Reclining Range

-

BF5-3 remium Suspension Seat for Demanding Stacker Operations with Full Adjustability

-

BF8-2 Wide-Angle Reclining Seat for Airport Tractors with 92° Adjustable Backrest

-

BF8-4 Reliable Semi-Suspension Seat for Airport Tow Tractors with Mechanical Suspension & 15° Backrest

-

BF10 Simple Compact Fixed Seat for Airport Ground Support Vehicles with Standard Mounting

-

BF16 High-Performance Suspension Seat for Stackers with Extensive Lumbar & Slide Adjustment

-

BF16M Extra-Wide Deluxe Passenger Seat for Spacious Tourist Vehicles

-

BF17 Comfort Suspension Seat for Stackers with Simplified Design & High Load Capacity

-

-

In the demanding world of construction, agriculture, and material handling, industrial vehicle seats are far more than simple places to sit. They are a critical interface between h...

READ MORE -

Industry Enterprises Deepen Production Technology, Welding Positioning Devices Achieve Patent Breakthroughs Recently, a number of enterprises in the industry have focused on the in...

READ MORE -

At the recently held international logistics exhibitions, a number of domestic enterprises made a collective appearance with their innovative achievements in equipment seats. They ...

READ MORE -

Driven by both the recovery of global infrastructure investment and the release of demand for replacement of construction machinery, the global construction machinery seat market i...

READ MORE

The Definitive Guide to Industrial Vehicle Seats: Standards, Safety, and Smart Selection

In the world of material handling, construction, and agriculture, the operator's seat is a critical interface between human and machine. High-performance industrial vehicle seats are engineered solutions that directly impact operator safety, long-term health, and overall productivity. This guide delves into the technical standards, ergonomic principles, and economic considerations behind modern seating, drawing on industry expertise to help you make an informed decision for your fleet and operators.

1. Decoding the Standards: JB/T13693-2019 and What It Means for You

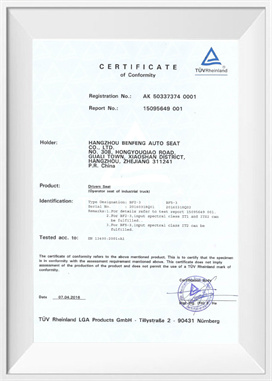

Compliance with national and international standards is the foundation of seat safety and performance. The Chinese machinery industry standard JB/T13693-2019, "Industrial Vehicle Driver Seat," sets critical benchmarks that manufacturers must meet.

Key Parameters and Testing Protocols:

- Dimensional Requirements and Adjustment Ranges: The standard specifies acceptable ranges for seat width, depth, backrest angle, and fore-aft travel to accommodate a diverse operator population.

- Strength and Durability Testing: Seats undergo rigorous static and dynamic load tests that simulate real-world forces and impacts. This includes cyclic fatigue testing to ensure the seat can withstand years of daily use.

- The Value of Compliance: For equipment manufacturers and end-users, specifying seats that meet JB/T13693-2019 minimizes liability risks and ensures a baseline of safety. Manufacturers involved in drafting this standard, such as Hangzhou Benfeng Auto Seat Co., Ltd., possess deep, practical knowledge of its application.

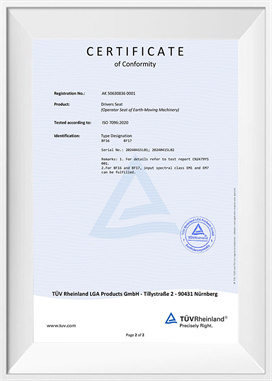

2. Vibration Isolation and the ISO 7096 Certification: Protecting Operator Health

Prolonged exposure to whole-body vibration (WBV) is a serious occupational hazard in industrial vehicles, linked to chronic back injuries and fatigue. The ISO 7096 standard is dedicated to measuring and certifying a seat's effectiveness in mitigating this risk.

Understanding Vibration Certification Levels:

- EM1 and EM7 Protection Levels: ISO 7096 defines different categories, such as EM1 and the more stringent EM7, based on the seat's vibration transmissibility. A seat with an EM7 rating offers a higher level of protection, meaning it isolates the operator from more vibration energy.

- Matching the Seat to the Application: Selecting the correct certification level depends on the machine's typical operating environment. For example:

- EM1 Level: Often suitable for electric forklifts operating on relatively smooth warehouse floors.

- EM7 Level: Highly recommended for loaders, rough-terrain forklifts, or agricultural tractors that frequently operate on uneven ground.

- Technology Behind the Certification: Achieving these levels requires advanced suspension systems, often incorporating air springs or sophisticated mechanical damping tuned to absorb shocks and dampen specific vibration frequencies.

3. From Design to Delivery: The Capabilities of a Modern Seat Manufacturer

The journey from a standard's requirement to a reliable, mass-produced seat highlights the importance of manufacturer capability. Key attributes include research involvement, scalable production, and a proven track record.

| Capability Pillar | Description and Impact |

| Standard-Setting Expertise | Active participation in drafting standards like JB/T13693-2019 indicates profound technical knowledge and a commitment to shaping industry safety benchmarks from the inside out. |

| Scalable Production | A substantial manufacturing footprint (e.g., a 14,000㎡ facility) and high annual output (e.g., 200,000 sets) demonstrate the ability to ensure consistent quality, meet large orders, and provide reliable supply chain support. |

| Global Partnership Portfolio | Long-term collaborations with renowned international brands (e.g., in material handling) serve as powerful validation of product quality, reliability, and engineering support. |

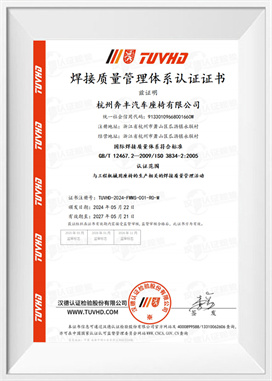

| Integrated Certification | Holding management system certifications (ISO 9001, 14001, 45001) and international product marks (CE) assures a systematic approach to quality, environment, safety, and global market compliance. |

4. Ergonomics and Efficiency: The Seat as a Productivity Tool

A superior seat is an investment in human capital. Good ergonomics translate directly into measurable operational benefits by reducing fatigue and improving the operator's focus and control.

Key Ergonomic Features and Their Benefits:

- Comprehensive Adjustability: Features like adjustable seat depth, lumbar support, armrests, and a weight-adaptive suspension allow operators to personalize their posture, promoting spinal health and reducing point pressure.

- Safety Integration: Modern seats are designed as part of a broader safety system, integrating seamlessly with seat belts, operator presence sensors (microswitches), and the vehicle's protective structures (ROPS/FOPS).

- The Productivity Link: A comfortable, well-supported operator is less fatigued, maintains better situational awareness, and can perform precision tasks more accurately and for longer periods, directly enhancing operational efficiency and reducing error rates.

5. Analyzing Total Cost of Ownership (TCO) for Industrial Seats

The smartest purchasing decision looks beyond the initial price tag. A Total Cost of Ownership analysis for industrial seats reveals why certified, high-quality seats are often more economical in the long run.

Components of the TCO Model:

- Initial Purchase Price: The upfront cost of the seat unit.

- Operational Costs: This includes the cost of downtime for seat replacement or repair, and more significantly, the potential costs associated with operator health issues, absenteeism, or compensation claims related to inadequate vibration isolation and poor ergonomics.

- Lifespan and Durability: High-quality seats built with robust materials and superior suspension components typically have a much longer service life, reducing replacement frequency.

- Residual Value Contribution: Well-maintained equipment with premium, comfortable seats often commands a higher resale or trade-in value.

Investing in a seat with proper certifications (ISO 7096, etc.) and ergonomic features is an investment in reducing the largest and most variable costs: those related to human performance and well-being.

FAQ: Your Questions on Industrial Vehicle Seats Answered

What is the single most important feature to look for in an industrial seat for operator health?

For long-term health protection, the most critical feature is a high-performance suspension system certified to a relevant ISO 7096 vibration isolation level (like EM1 or EM7). While comfort adjustments are important, it is the seat's ability to attenuate harmful whole-body vibration that directly prevents chronic spinal injuries and fatigue over thousands of operating hours. Always prioritize the suspension certification that matches your specific working terrain.

How does a manufacturer's role in creating industry standards benefit me as a buyer?

When a manufacturer, such as Hangzhou Benfeng Auto Seat Co., Ltd., helps draft standards like JB/T13693-2019, it provides you with a significant advantage. It means their engineering team possesses an authoritative, in-depth understanding of the safety requirements and test protocols. Consequently, their products are not merely designed to pass minimum tests but are often engineered to exceed standard expectations from the initial design phase, offering you built-in assurance of compliance, safety, and durability.

Can I replace a seat myself, or do I need a professional technician?

While simple bolt-on replacements might be feasible for mechanically inclined personnel, we strongly recommend professional installation for several key reasons:

- Safety Criticality: The seat is a primary safety component. Incorrect installation can compromise the integrity of the seat belt anchors, operator presence sensor, or the seat's own mounting, leading to failure in an accident.

- Technical Adjustment: Proper installation includes calibrating the suspension for the operator's weight and ensuring all adjustment mechanisms function correctly, which requires specific knowledge.

- Warranty Preservation: DIY installation may void the product warranty. Professional service ensures the installation is documented and performed according to the manufacturer's specifications.

How often should industrial vehicle seats be inspected or replaced?

There is no fixed timeline, as wear depends on usage hours and operating conditions. Implement a proactive inspection schedule:

- Daily/Operator Check: Quick visual check for obvious damage, tears, or malfunctioning adjustments.

- Scheduled Maintenance Inspection (e.g., Quarterly): A technician should check for worn suspension components (loss of damping, bottoming out), structural integrity of the frame and mounting points, and the function of integrated safety switches.

- Replacement Triggers: Replace seats immediately if you find collapsed cushioning, failed suspension, cracked welds or frame, or if operators consistently report discomfort or pain, indicating the seat no longer provides adequate support or isolation.

Are air suspension seats always better than mechanical suspension seats?

Not always; the "best" choice depends on the application and budget. Here’s a comparison to guide your decision:

| Aspect | Air Suspension Seats | Mechanical Suspension Seats |

| Vibration Isolation | Generally superior, especially for low-frequency vibrations. Offers a smoother, "floating" feel. | Effective for absorbing larger shocks but may transmit more high-frequency vibration. |

| Adjustability | Often feature automatic weight adjustment and fine-tuned damping control. | Usually have manual weight adjustment with a more limited range. |

| Cost & Complexity | Higher initial cost and potentially higher maintenance complexity. | More cost-effective upfront and typically simpler to maintain. |

| Ideal For | High-hour machines in consistently rough terrain (e.g., loaders, mining vehicles). | Machines operating on moderately uneven ground or where budget is a primary constraint. |

The key is to match the suspension type to the machine's duty cycle and the vibration exposure level defined in ISO 7096.

中文简体

中文简体 English

English Français

Français Español

Español عربى

عربى