1. Introduction In various industrial environments, operator comfort and safety directly impact work efficiency and long-term health. As a critical component of industrial vehicles...

READ MORE-

(86)-0571-82550327

-

info@bfseats.com

-

Other Industrial Vehicle Seat Manufacturers

In addition to mainstream machinery and equipment, Benfeng also provides tailored seating solutions for unique industrial applications.

For airport tractors, we prioritize all-day durability and operator support to enable continuous ground support operations. The seats we design for industrial platform trucks are shock-absorbing, capable of handling vibrations from uneven surfaces and ensuring stability during heavy-load transportation within the facility.

In high-density warehousing, operators of stacker cranes require precise control. Our design provides the necessary ergonomic support and clear visibility for accurate, high-altitude handling operations.

For non-road tourist vehicles in resorts or large campuses, we prioritize robust construction and enhanced passenger comfort to provide a reliable and comfortable ride experience.

Across these diverse platforms - ranging from logistics transportation to aviation ground equipment to tourist vehicles - Benfeng seats, with their tailored designs and proven reliability, ensure safety, comfort, and efficiency.

-

BF17 Comfort Suspension Seat for Stackers with Simplified Design & High Load Capacity

-

-

In the demanding world of construction, agriculture, and material handling, industrial vehicle seats are far more than simple places to sit. They are a critical interface between h...

READ MORE -

Industry Enterprises Deepen Production Technology, Welding Positioning Devices Achieve Patent Breakthroughs Recently, a number of enterprises in the industry have focused on the in...

READ MORE -

At the recently held international logistics exhibitions, a number of domestic enterprises made a collective appearance with their innovative achievements in equipment seats. They ...

READ MORE -

Driven by both the recovery of global infrastructure investment and the release of demand for replacement of construction machinery, the global construction machinery seat market i...

READ MORE

What Factors Determine the Comfort and Durability of Industrial Vehicle Seats?

With the continuous development of modern industry and machinery, the comfort and safety of Industrial Vehicle Seats have become crucial factors that cannot be ignored. Whether in forklifts, loaders, cleaning equipment, or other construction machinery, the comfort and health of the operator directly affect work efficiency and long-term safety. So, why are industrial vehicle seats so important to operators?

How Does Seat Design Affect Operator Work Efficiency?

The design of industrial vehicle seats is not only about comfort but also closely related to the health and work efficiency of the operator. An ergonomic seat can provide good support for the operator, reduce discomfort during long-term operation, and thus improve work efficiency.

Ergonomic Design: Health and Efficiency in Harmony

Prolonged seated operation, especially in high-vibration or bumpy conditions, easily leads to operator fatigue and physical discomfort. Especially in high-intensity operations such as handling and loading, traditional seat designs often fail to effectively alleviate physical pressure, thus affecting operator performance.

Adopting an ergonomic design, the seat better conforms to the curves of the human body, providing support for the waist, back, and neck, reducing unnecessary pressure. Hangzhou Benfeng Automotive Seating Co., Ltd., as one of China's leading industrial vehicle seat manufacturers, is committed to providing customized seat solutions for various industrial vehicles, ensuring operators maintain a comfortable posture, reduce fatigue, and improve work efficiency during long working hours.

How is Safety Ensured Through Seat Design?

Seat safety is another crucial design factor that cannot be ignored. When using industrial vehicles, operators frequently encounter situations such as rapid acceleration, braking, or bumps. The seat design and fixation method directly affect operator safety in these special circumstances.

Seat Protective Functions

Modern industrial vehicle seats are typically equipped with multiple protective functions, such as drop protection, tilt adjustment, and pneumatic lifting systems. These functions not only keep operators stable during rapid movement but also reduce the risk of injury in the event of an accident.

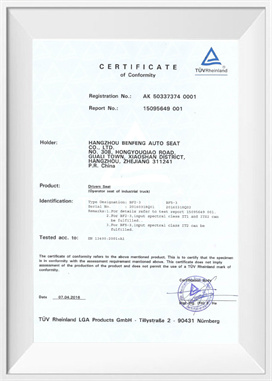

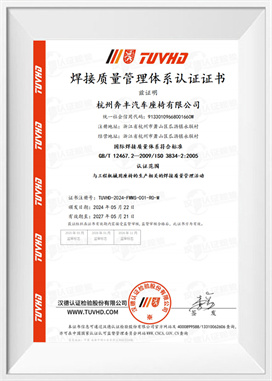

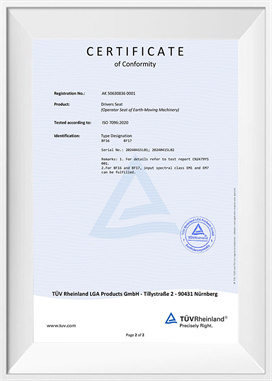

Hangzhou Benfeng Auto Seat Co., Ltd.'s industrial vehicle seats have passed ISO9001 and ISO3834 quality management certifications. All seats undergo rigorous safety testing and quality control to ensure the safety of every operator during use. For example, the company's products have obtained European EN13490 IT1, 1T2, ISO7096 EM1, and EM7 international safety certifications, meeting the safety standards of different global markets.

How High Are the Requirements for Seats During Long-Term Use?

In industrial environments, the durability and comfort of seats are particularly important. Unlike home seats, industrial vehicle seats need to withstand long-term, frequent use and high-intensity working environments. Equipment operators frequently use the seats in different weather conditions, ground conditions, and working environments, which requires the seats to have high wear resistance and durability.

Application of Highly Durable Materials

High-strength seat materials effectively cope with the harsh environment of the construction site, preventing premature damage to the seats due to wear, corrosion, or external impacts. Hangzhou Benfeng Auto Seat Co., Ltd.'s seating products utilize advanced materials such as high-strength plastics, metal alloys, and wear-resistant seat cushions. These materials effectively extend the lifespan of the seats, ensuring their reliability and comfort during long-term use.

The company also continuously innovates, launching multi-functional seats that are waterproof, corrosion-resistant, and UV-resistant, making them particularly suitable for outdoor environments and high-humidity areas. Whether on construction sites, in ports, or logistics parks, Hangzhou Benfeng's seats meet the demands of high-intensity use.

Environmental Protection and Sustainable Development in Seating Design

With increasingly stringent environmental regulations and a stronger industry trend towards sustainable development, the design of industrial vehicle seats is increasingly considering environmental protection and recyclability. Seating materials must not only guarantee high performance but also consider their environmental properties to avoid burdening the environment.

The Trend of Eco-Friendly Design

Hangzhou Benfeng Auto Seat Co., Ltd. consistently focuses on the industry's environmental needs, incorporating recyclable materials into its product design, reducing energy consumption in the production process, and optimizing production processes to reduce waste and exhaust emissions. This not only helps the company comply with international environmental standards but also provides customers with greener and more environmentally friendly product options.

Why Choose Industrial Vehicle Seats from Hangzhou Benfeng Auto Seat Co., Ltd.?

Since its establishment in 2007, Hangzhou Benfeng Auto Seat Co., Ltd. has focused on the research and development and production of industrial vehicle seats, possessing many years of industry experience. As one of the drafting units of China's "Industrial Vehicle Driver Seats" standard, Hangzhou Benfeng Auto Seat Co., Ltd. deeply understands the crucial role of seats for industrial vehicle operators. Therefore, every product from the company strictly adheres to industry standards, striving to provide global customers with the safest, most comfortable, and most durable seat solutions.

Frequently Asked Questions (FAQ)

Q1: Can industrial vehicle seats from Hangzhou Benfeng Auto Seat Co., Ltd. be customized?

A1: Yes, Hangzhou Benfeng Auto Seat Co., Ltd. provides customized seat solutions. Customers can choose the seat material, color, functions, etc., according to their specific needs to meet different work environments and individual requirements.

Q2: What safety certifications do Hangzhou Benfeng Auto Seat Co., Ltd. seats have?

A2: Our seating products have passed ISO9001, ISO3834, ISO14001, and ISO45001 certifications, and have obtained CE certification. Some products have also passed European EN13490 IT1, 1T2 and ISO7096 EM1, EM7 certifications, meeting international safety standards.

Q3: Which industrial vehicles are Hangzhou Benfeng Auto Seat Co., Ltd.'s seats suitable for?

A3: Hangzhou Benfeng Auto Seat Co., Ltd.'s seats are widely used in forklifts, loaders, sweepers, tractors, and other industrial vehicles. Our seats can be designed according to different working conditions to meet the needs of various mechanical equipment.

中文简体

中文简体 English

English Français

Français Español

Español عربى

عربى