1. Introduction In various industrial environments, operator comfort and safety directly impact work efficiency and long-term health. As a critical component of industrial vehicles...

READ MORE-

(86)-0571-82550327

-

info@bfseats.com

-

Construction Machinery Seats Manufacturers

Benfeng Seats focuses on providing high-quality seating solutions for various types of construction machinery and equipment, covering multiple fields such as earthmoving machinery (excavators, loaders, bulldozers, graders), lifting and hoisting equipment (automobile/crawler cranes, tower cranes, construction elevators), pile driving machinery (rotary drilling rigs, pile drivers, static pile drivers), road construction machinery (rollers, asphalt pavers, milling machines), and concrete equipment (concrete pump trucks, concrete distributors).

The seats are made of black vinyl and velvet fabric, balancing durability and comfort. Relying on our independent research and development team, we can provide customized services based on samples and drawings; A professional quality control team and testing laboratory implement full process quality control to ensure product reliability. With advanced production equipment, 95% of key components are independently produced, with an annual output of 200000 sets, which can meet different procurement requirements, and the average delivery time is only 15-20 days, quickly responding to customer needs.

-

BF20 Ergonomic Heavy-Duty Adjustable Construction Seat for Truck Cranes with ISO

-

BF21 Comfortable Durable Suspension Construction Seat for Excavator with CE Mark

-

-

In the demanding world of construction, agriculture, and material handling, industrial vehicle seats are far more than simple places to sit. They are a critical interface between h...

READ MORE -

Industry Enterprises Deepen Production Technology, Welding Positioning Devices Achieve Patent Breakthroughs Recently, a number of enterprises in the industry have focused on the in...

READ MORE -

At the recently held international logistics exhibitions, a number of domestic enterprises made a collective appearance with their innovative achievements in equipment seats. They ...

READ MORE -

Driven by both the recovery of global infrastructure investment and the release of demand for replacement of construction machinery, the global construction machinery seat market i...

READ MORE

Why Choosing the Right Construction Machinery Seats is Crucial for Improving Work Efficiency?

Construction machinery seats play a vital role in industrial sectors such as construction, mining, and warehousing. Whether it's heavy machinery like forklifts, loaders, or excavators, operator comfort and safety directly impact their work efficiency and health.

Functional Requirements for Construction Machinery Seats

Enhancing Comfort: Reducing Fatigue and Discomfort

Construction machinery often requires operators to work in the driver's seat for extended periods, making seat comfort paramount. A well-designed seat can effectively reduce operator fatigue, especially in rugged working environments. Seat elasticity, cushioning systems, and ergonomic design all contribute to reducing operator stress and improving work efficiency and operational precision.

Enhancing Safety: Preventing Injuries and Accidents

The operating environment for construction machinery is fraught with potential hazards, especially for heavy machinery requiring precise control. In this environment, seat safety is paramount. A suitable seat must not only meet national standards but also possess excellent stability, impact resistance, and anti-slip design. High-quality seats effectively reduce the risk of operator injury during mechanical vibrations or collisions, ensuring their safety.

Providing Stability: Maintaining Precise Operation

Operating construction machinery typically requires precise movements and a stable driving posture. A stable seat effectively reduces vibration and bumps, allowing operators to focus more on the machinery without being distracted by harsh environmental conditions. This positively impacts productivity and reduces accidents caused by improper operation.

How does Hangzhou Benfeng Auto Seat Co., Ltd.'s seat design stand out?

Years of Industry Deep Cultivation: Accumulated Professional Experience

Since its establishment in 2007, Hangzhou Benfeng Auto Seat Co., Ltd. has focused on the research and development and production of various high-performance construction machinery seats. Through years of development, leveraging its rich industry experience and technological accumulation, the company has become one of the drafting units of the Chinese machinery industry standard "JB/T13693-2019 Industrial Vehicle Driver's Seats". The company's production base covers 14,000 square meters, with an annual production capacity of 200,000 seats, covering multiple fields such as forklifts, loaders, and cleaning equipment, meeting the needs of a wide range of customers.

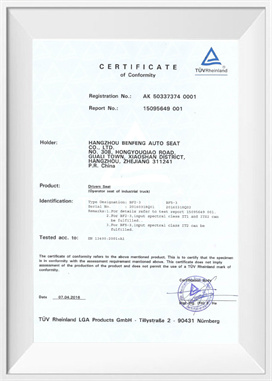

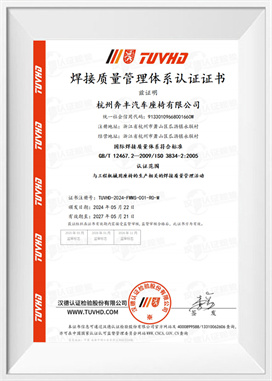

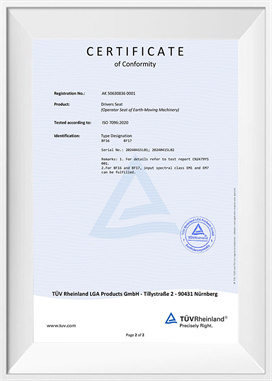

High-Quality Certifications: A Guarantee of Safety and Reliability

The company has passed international certifications such as ISO9001 Quality Management System, ISO3834 Welding Quality Management System, ISO14001 Environmental Management System, and ISO45001 Occupational Health and Safety Management System, ensuring the high quality and safety of every seat. Meanwhile, Benfeng Seats has also obtained multiple national invention patents and utility model patents, and its products have CE certification and have passed international certifications such as European EN13490 and ISO7096, demonstrating its global competitiveness.

Customized Services: Meeting Individual Customer Needs

Hangzhou Benfeng Auto Seat Co., Ltd. is committed to providing customized seating solutions for its customers. From design and development to production, Benfeng Auto Seat Co., Ltd., with its strong R&D team and advanced production processes, can provide tailor-made seating products according to the different needs of its customers. This personalized service greatly improves the adaptability of the seats, ensuring that each seat can maximize the satisfaction of the construction environment and the needs of the operators.

How to Choose the Right Construction Machinery Seat?

Consider the Working Environment: Adaptable Design

Different construction machinery has different working environments and operational requirements. When choosing a chair, the first consideration should be the working environment. For example, forklift operators need to navigate confined spaces and frequent turning, so their chairs need to be flexible and comfortable. Loader and excavator operators, on the other hand, typically face environments with significant vibration and bumps, requiring chairs with strong shock absorption and stability.

Ergonomic Design: Providing Optimal Support

Ergonomic design is a crucial factor when choosing a construction machinery chair. The chair should be designed according to the human body's physiological structure to provide the most comfortable sitting posture and maximum support. Appropriate ergonomic design can help reduce pressure on the operator's lower back and back, preventing occupational diseases caused by prolonged operation.

Chair Material and Durability

Construction machinery often faces high-intensity workloads and harsh environmental conditions, making the chair's material and durability particularly important. A high-strength metal frame, wear-resistant seat fabric, and a high-quality shock absorption system ensure that the chair maintains good performance and appearance even after prolonged use.

Frequently Asked Questions (FAQ)

1. What types of construction machinery chairs are available?

Construction machinery chairs are typically categorized based on the type of machinery and the usage scenario. For example, forklift seats, loader seats, excavator seats, etc. Each type of seat needs to be designed according to different operating environments and comfort requirements to provide optimal comfort and safety.

2. What are the quality standards for seats from Hangzhou Benfeng Auto Seat Co., Ltd.?

Hangzhou Benfeng Auto Seat Co., Ltd. strictly adheres to international quality management systems such as ISO9001, ISO3834, ISO14001, and ISO45001 in its production. All products have passed CE certification and have obtained invention patents in multiple countries, ensuring the high quality and safety of each seat.

3. How to choose a suitable construction machinery seat?

When choosing a construction machinery seat, several factors should be considered, including the working environment, ergonomic design, seat material, and durability. Choosing the right seat based on the specific type of machinery and working conditions can improve operator comfort and work efficiency.

中文简体

中文简体 English

English Français

Français Español

Español عربى

عربى