1. Introduction In various industrial environments, operator comfort and safety directly impact work efficiency and long-term health. As a critical component of industrial vehicles...

READ MORE-

(86)-0571-82550327

-

info@bfseats.com

-

Cleaning Equipment Seat Manufacturers

Benfeng Seats is dedicated to providing professional, durable, and comfortable driving seat solutions for various modern and high-performance cleaning machinery.

Our seats are designed to match driving floor cleaning equipment, covering a wide range of application scenarios for driving floor sweepers (such as factory workshops, large warehouses, shopping malls, parking lots, and municipal roads) and driving floor scrubbers (such as supermarkets, hospitals, airport terminals, and large office buildings with extremely high cleanliness requirements). At the same time, we also provide customized seats for special and harsh environments, including high-precision airport runway/apron cleaning vehicles, cleaning vehicles for dealing with large amounts of dust and residue at port terminals, and heavy-duty cleaning vehicles for handling metal debris and oil pollution in industrial workshops such as automobile factories and machinery factories.

The core product is made of high-quality black vinyl fabric, which has excellent wear resistance, stain resistance, and easy cleaning characteristics, perfectly adapting to the cleaning environment. With our independent research and development team, we can provide flexible customization services (supporting sample and image) to meet your unique needs. A strict quality control system runs through the entire process from raw materials to finished products, and a professional testing laboratory ensures the reliable quality of each set of seats. Relying on advanced production equipment and 95% independent production capacity of key components, we have a strong production capacity advantage of 200000 sets per year, and can provide industry-leading fast delivery time (average 15-30 days), efficiently responding to the procurement needs of customers of different scales.

-

BF1-1 Durable PVC Cleaning Equipment Seats for Ride-On Sweepers

-

BF1-2 Foldable-Back Cleaning Equipment Seats for Ride-On Sweepers

-

BF1-3 Fully Certified CE/ISO Cleaning Equipment Seats for Global Compliance

-

BF8-2 ISO 3834 Certified Industrial Cleaning Equipment Seats for Metal Workshops

-

BF8-4LC Ergonomic Shock-Absorbing Cleaning Equipment Seats with Two-point Seat Belt

-

BF10 Dual-Tone PVC Cleaning Equipment Seats with Enhanced Visibility

-

BF11 Low-Maintenance Cleaning Equipment Seats with Wipe-Clean PVC

-

-

In the demanding world of construction, agriculture, and material handling, industrial vehicle seats are far more than simple places to sit. They are a critical interface between h...

READ MORE -

Industry Enterprises Deepen Production Technology, Welding Positioning Devices Achieve Patent Breakthroughs Recently, a number of enterprises in the industry have focused on the in...

READ MORE -

At the recently held international logistics exhibitions, a number of domestic enterprises made a collective appearance with their innovative achievements in equipment seats. They ...

READ MORE -

Driven by both the recovery of global infrastructure investment and the release of demand for replacement of construction machinery, the global construction machinery seat market i...

READ MORE

Why do high-quality cleaning equipment seats effectively reduce operator fatigue?

In industrial equipment, seats are often considered insignificant accessories, but their design and quality directly impact operator efficiency and comfort, especially in specialized applications like cleaning equipment. Whether it's a floor scrubber, sweeper, or other cleaning equipment, prolonged operation can lead to fatigue, discomfort, and even affect work quality. Therefore, choosing a suitable cleaning equipment seat is not only about comfort but also a crucial measure for improving work efficiency and ensuring safety.

Cleaning Equipment Seat Design: Comfort and Safety Go Hand in Hand

Cleaning equipment operators typically operate the equipment for extended periods, requiring seats that are not only ergonomic but also highly comfortable. Cleaning equipment seats need to be adjustable to accommodate the operator's body shape, including height, tilt, and depth, ensuring the operator finds the most natural sitting posture. The seat's material, elasticity, and ventilation also affect operator comfort. High-quality seat materials effectively absorb vibrations, reduce fatigue, and enhance the operator's work experience.

From a safety perspective, the design of cleaning equipment seats must meet a range of safety standards. A well-designed seat not only improves operator comfort but also provides better support in emergencies. For example, a seatbelt effectively prevents operator injury from severe equipment vibrations or accidents during operation.

The Relationship Between Cleaning Equipment Seats and Work Efficiency

Have you ever experienced back pain or difficulty concentrating due to an uncomfortable seat? An uncomfortable seat can cause operator fatigue, affecting operational accuracy and efficiency. This is especially true for cleaning equipment that requires frequent operation; an inadequate seat design can distract the operator, significantly reducing work efficiency.

For example, operators of floor scrubbers need to frequently adjust their seats to adapt to different driving postures, requiring well-adjustable seats. Prolonged sitting also necessitates sufficient support. For cleaning equipment, seat comfort directly impacts the smoothness and precision of operation. If the seat does not provide adequate support, the operator is prone to fatigue, potentially affecting the normal operation of the equipment and reducing work efficiency.

Material Selection for Cleaning Equipment Seats

The choice of materials for cleaning equipment seats is crucial to their durability and comfort. During the use of cleaning equipment, the seats are exposed to various environmental conditions, including moisture, dust, and extreme temperatures, requiring highly durable materials. Common materials for cleaning equipment seats include PU leather, nylon fabric, and high-elasticity rubber. These materials are waterproof, dustproof, and abrasion-resistant, effectively extending the seat's lifespan.

Simultaneously, the seat filling material should be high-elasticity, high-density sponge or memory foam. These materials provide even support according to the curves of the human body, reducing discomfort from prolonged use. Furthermore, breathability is also critical, especially in high-temperature and humid working environments. Good breathability helps operators stay dry and avoids discomfort from prolonged sitting.

Why Choose Hangzhou Benfeng's Cleaning Equipment Seats?

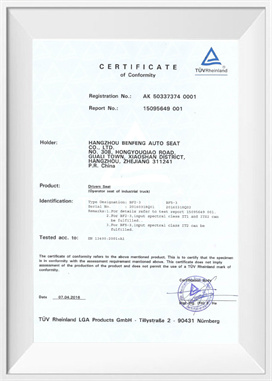

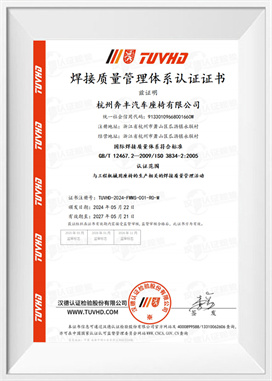

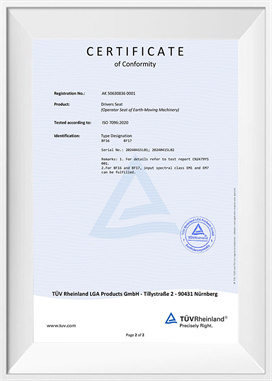

As a professional company specializing in the design and production of cleaning equipment seats, Hangzhou Benfeng Auto Seat Co., Ltd. is committed to providing customers with safe, comfortable, and high-quality seating solutions. With years of industry experience and technological accumulation, the company has become a partner of numerous well-known domestic and international brands and has obtained multiple international quality certifications, including ISO9001, ISO3834, ISO14001, and ISO45001.

Our Advantages

Industry-Leading Design and Innovation Capabilities

Hangzhou Benfeng is committed to the research and development of cleaning equipment seats. With numerous national invention patents and utility model patents, our seat products have significant advantages in comfort, durability, and safety. Especially for cleaning equipment operating in special environments, our seat designs can be customized to meet specific needs.

Strict Quality Management System

Our company has passed a series of quality management system certifications, including ISO9001, ensuring that every product meets international standards during the production process. We also conduct rigorous quality testing on our products according to international certification standards such as European EN13490 IT1 and ISO7096 EM1, ensuring the reliability and safety of our products worldwide.

Stable Supply Chain and Efficient Delivery Capabilities

With a 14,000㎡ production base and an annual production capacity of 200,000 units, Hangzhou Benfeng Auto Seat Co., Ltd. can provide customers with a stable product supply and ensure delivery within the stipulated time. Our efficient production and excellent after-sales service have been highly praised by customers both domestically and internationally.

Frequently Asked Questions (FAQ)

1. Why is the design of cleaning equipment seats so important?

The design of cleaning equipment seats directly affects the operator's comfort and safety, impacting their work efficiency. A good seat design can reduce fatigue and ensure that the operator maintains good posture and concentration during long periods of operation.

2. How to choose a suitable cleaning equipment seat?

When choosing a cleaning equipment seat, it is necessary to consider the seat's comfort, durability, adjustability, and safety. A high-quality seat should have good support and be adjustable according to the operator's body shape to provide the best driving experience.

3. What are the advantages of Hangzhou Benfeng Auto Seat Co., Ltd.'s cleaning equipment seats?

Hangzhou Benfeng Auto Seat Co., Ltd.'s cleaning equipment seats offer significant advantages in design, comfort, durability, and safety. With years of industry experience and international certifications such as ISO9001, we provide customers with high-quality, highly reliable seating solutions.

中文简体

中文简体 English

English Français

Français Español

Español عربى

عربى