1. Introduction In various industrial environments, operator comfort and safety directly impact work efficiency and long-term health. As a critical component of industrial vehicles...

READ MORE-

(86)-0571-82550327

-

info@bfseats.com

-

Durable Agricultural Machinery Seats Manufacturers

Benfeng Seats is deeply rooted in the field of agricultural machinery. We focus on developing high-performance seating systems, providing triple core guarantees of shock absorption, adjustability, and safety for tractors, combine harvesters, telescopic arm forklifts, transplanters, various earthmoving equipment (excavators/loaders), seeders, balers, etc. Special challenges for agricultural work scenarios:

1. Ultimate shock absorption: With mechanical suspension technology, it can reduce vibration transmission by up to 54% and adapt to a weight range of 40-135kg, effectively preventing lumbar spine injuries;

2. Human machine adaptation: Multi directional adjustment mechanism (height/inclination/depth/lumbar support) matches operators of different body types, and transplanting machines and other equipment are equipped with electric slide rail systems to dynamically coordinate work posture;

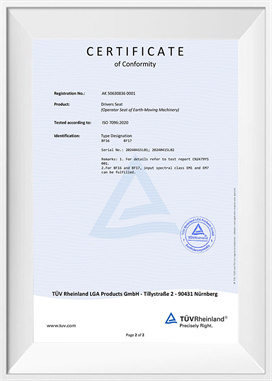

3. Safe and durable: Complies with ISO 7096 vibration standard, comes standard with two-point seat belts, uses flame-retardant fabric and high resilience sponge, black vinyl/velvet and other wear-resistant materials to cope with outdoor environments.

Based on an annual production capacity of 200000 sets and a 95% in-house production capacity for core components, we provide customized services for full process quality control - from seat structure to fabric solutions, delivered quickly within 15-20 days, making the cockpit of each agricultural machinery a reliable core pivot for productivity.

-

BF16 Premium Ergonomic Suspension Agricultural Seat for Tractors with CE ISO 9001

-

BF16M Comfortable Adjustable Durable Agricultural Seat for Loaders with PVC or Fabric

-

BF17 Premium Ergonomic Shock-Absorbing Seat for Agricultural Equipment with ISO 7096 Certification

-

-

In the demanding world of construction, agriculture, and material handling, industrial vehicle seats are far more than simple places to sit. They are a critical interface between h...

READ MORE -

Industry Enterprises Deepen Production Technology, Welding Positioning Devices Achieve Patent Breakthroughs Recently, a number of enterprises in the industry have focused on the in...

READ MORE -

At the recently held international logistics exhibitions, a number of domestic enterprises made a collective appearance with their innovative achievements in equipment seats. They ...

READ MORE -

Driven by both the recovery of global infrastructure investment and the release of demand for replacement of construction machinery, the global construction machinery seat market i...

READ MORE

Application of Damping Technology in Agricultural Machinery Seats and the ISO 7096 Standard

Agricultural operations often take place in rugged and uneven fields, where all-day vibration exposure can cause serious harm to the driver's spine and health. Therefore, high-performance AGRUCULTURAL MACHINERY SEATS must be equipped with advanced suspension systems to mitigate these risks.

Key Technical Parameters

- ISO 7096 EM1 / EM7: Vibration testing standards for different agricultural machinery (e.g., crawler vs. wheeled), measuring the vibration acceleration transmitted to the driver.

- Suspension Travel: Determines the buffering capacity of the seat on uneven ground.

- Weight Adjustment Range: Usually between 50kg to 130kg, ensuring drivers of different weights achieve optimal damping effects.

Industry Practice and Corporate Capability

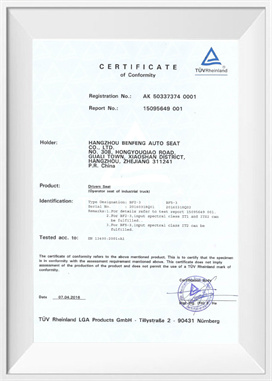

Hangzhou Benfeng Auto Seat Co., Ltd., established in 2007, has focused on the development of off-road construction machinery seats for many years. With a 14,000 square meter production base and an annual output of 200,000 sets, the company utilizes ISO9001 certified precision manufacturing processes to produce high-end seats that comply with ISO7096 EM1 and EM7 standards. These seats effectively reduce harmful vibrations by over 50%, protecting driver health.

Safety Architecture of Agricultural Machinery Seats in Compliance with EN 13490

In agricultural environments involving rollover risks and heavy object operations, AGRICULTURAL MACHINERY SEATS must possess extremely high structural strength and safety. The European EN 13490 standard is an important criterion for measuring this safety level.

Key Technical Parameters

- EN 13490 IT2: An advanced protection level suitable for uneven terrain and high-impact environments.

- Seat Belt System: Integration method and anchor strength of two-point or three-point seat belts.

- Endurance Testing: Structural stability of the seat under repeated impact and loading.

Industry Practice and Corporate Capability

Hangzhou Benfeng Auto Seat Co., Ltd. strictly follows international safety regulations. Some of their AGRICULTURAL MACHINERY SEATS products have successfully passed EN13490 IT1 and IT2 certifications. The company's products not only hold international CE certification but also possess multiple national invention and utility model patents, ensuring the safety and reliability of the seat under extreme operating conditions for loaders and tractors.

Guidance of JB/T13693-2019 on Agricultural Machinery Seats

With the improvement of agricultural mechanization in China, domestic quality requirements for AGRICULTURAL MACHINERY SEATS have become increasingly strict. JB/T13693-2019 "Industrial Vehicle Driver Seat" is an important technical basis for this industry.

Key Technical Parameters

- Standard Number: JB/T13693-2019.

- Scope of Application: Covers the design, manufacturing, and acceptance of driver seats for industrial and agricultural vehicles such as tractors and harvesters.

- Core Drafting Units: Enterprises participating in the formulation of this standard represent the top technical level in the industry.

Industry Practice and Corporate Capability

As one of the primary units setting this standard, Hangzhou Benfeng Auto Seat Co., Ltd. demonstrates its technical authority within the industry. Recognized as a "Zhejiang High-tech Enterprise" and "Specialized and New Enterprise," the company incorporates high-standard requirements into the entire production process of AGRICULTURAL MACHINERY SEATS, controlling product quality from the source.

Customized Design for Tractors and Combine Harvesters

Different agricultural machinery has vastly different requirements for seats. For instance, tractors require comfort for long-duration driving, while combine harvesters need to withstand high dust and violent vibration environments.

Key Technical Parameters

- Height and Tilt Adjustment: Adapting to the driving visibility requirements of different machine models.

- Material Selection: Waterproof, oil-resistant, and wear-resistant black vinyl or flame-retardant fabrics.

- Optional Accessories: Armrests, document boxes, air conditioning functions.

Industry Practice and Corporate Capability

Hangzhou Benfeng Auto Seat Co., Ltd. is committed to providing customized seat solutions for material handling forklifts, loaders, tractors, and cleaning equipment. The company possesses a strong R&D and design team capable of personalized development based on the special operating condition requirements of clients. Maintaining friendly cooperation with well-known brands such as LiuGong and MIMA, the company provides customized products that are both comfortable and durable.

Innovative Practice of Ergonomics in Agricultural Machinery Seats

Modern AGRICULTURAL MACHINERY SEATS must not only be "sittable" but also "comfortable." Excellent ergonomic design can significantly reduce driver fatigue and improve operational efficiency.

Key Technical Parameters

- Lumbar Support: Adjustable support design to prevent lumbar strain.

- Cushion Depth and Width: Dimensions designed to fit drivers of different body shapes.

- Anti-slip Texture: Ensures the driver maintains a stable sitting posture on bumpy roads.

Industry Practice and Corporate Capability

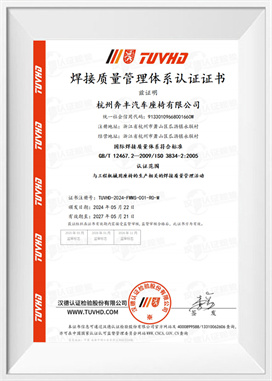

Hangzhou Benfeng Auto Seat Co., Ltd. has passed multiple system certifications including ISO3834 (Welding Quality System), ISO14001 (Environmental Management), and ISO45001 (Occupational Health and Safety). This indicates that in producing AGRICULTURAL MACHINERY SEATS, the company focuses not only on the physical performance of the product but also on the harmony of "Man-Machine-Environment." The products provided to global top brands like Mitsubishi Logisnext and KION fully reflect the perfect combination of ergonomics, safety, and comfort.

| Company Name | Hangzhou Benfeng Auto Seat Co., Ltd. |

| Year Established | 2007 |

| Production Base | 14,000 square meters |

| Annual Output | 200,000 sets |

| Key Certifications | ISO9001, ISO3834, ISO14001, ISO45001, CE, EN13490 IT1/IT2, ISO7096 EM1/EM7 |

| Key Partners | Mitsubishi Logisnext, NICHIYU, HANGCHA, EP, JUNGHEINRICH, Linde, KION, LiuGong, MIMA, GOODSENSE |

FAQ

Why is ISO 7096 certification critical for Agricultural Machinery Seats?

ISO 7096 certification is essential because it measures the seat's ability to reduce whole-body vibration (WBV), which is a major health hazard for agricultural machinery operators. High-quality seats compliant with standards like EM1 and EM7 ensure that the suspension system effectively absorbs shocks from uneven terrain. Hangzhou Benfeng Auto Seat Co., Ltd. manufactures AGRICULTURAL MACHINERY SEATS that meet these rigorous standards, significantly reducing driver fatigue and preventing long-term spinal injuries.

What are the differences between EN 13490 IT1 and IT2 ratings for farm equipment seats?

The EN 13490 standard classifies seats based on their intended usage environment. IT1 rated seats are designed for vehicles operating on smoother surfaces, providing basic protection. In contrast, IT2 rated seats are built for rough, off-road conditions typical of heavy agricultural work, offering superior structural strength and damping capabilities. Choosing IT2 seats for high-impact machinery ensures better safety and durability for AGRICULTURAL MACHINERY SEATS.

Can Agricultural Machinery Seats be customized for specific tractor models?

Yes, customization is a standard service offered by leading manufacturers. Hangzhou Benfeng Auto Seat Co., Ltd. provides tailored AGRICULTURAL MACHINERY SEATS solutions that can be adapted to specific tractor models, combine harvesters, and loaders. Customization options include specific mounting interfaces, material choices like waterproof vinyl, and additional features such as armrests or air-suspension systems to match the exact requirements of the agricultural machinery.

How does the JB/T13693-2019 standard influence the quality of Agricultural Machinery Seats?

As the Chinese machinery industry standard for "Industrial Vehicle Driver Seat," JB/T13693-2019 sets the benchmark for quality and safety in the domestic market. Hangzhou Benfeng Auto Seat Co., Ltd., being one of the standard-setting units, integrates these strict requirements into their production lines. This ensures that their AGRICULTURAL MACHINERY SEATS not only meet but often exceed industry expectations for reliability, safety, and ergonomic design.

What features should be prioritized when selecting seats for combine harvesters?

When selecting seats for combine harvesters, prioritizing features that handle high vibration and dust is crucial. Look for AGRICULTURAL MACHINERY SEATS with robust mechanical suspension (preferably weight-adjustable), durable and easy-to-clean materials like heavy-duty vinyl, and integrated safety belts. Additionally, ergonomic features such as lumbar support and adjustable armrests are vital for maintaining operator comfort during long harvesting hours.

中文简体

中文简体 English

English Français

Français Español

Español عربى

عربى